Nagasaki’s 165 years of innovation — from shipbuilding to jet engines

Ships are one of mankind’s earliest but still most important technologies. They have facilitated the pursuit of global trade, knowledge and exploration for millennia.

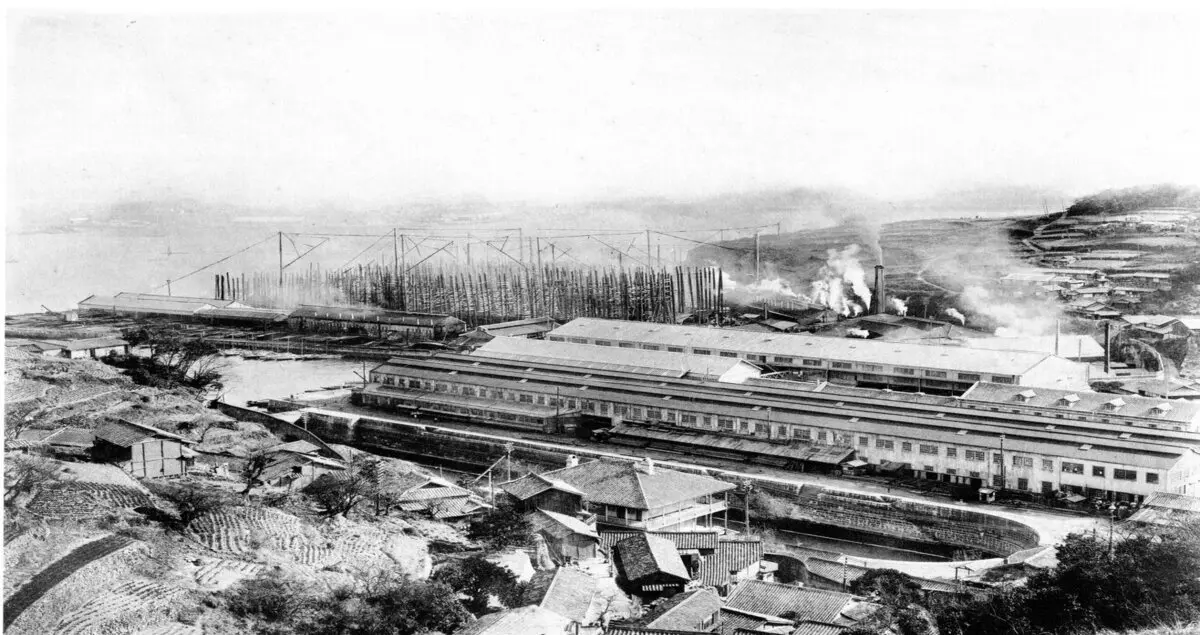

Shipyards share that rich history, too, not least the Nagasaki Shipyard and Machinery Works in Japan, parts of which have now achieved UNESCO World Heritage status as being sites of Japan’s Meiji industrial revolution.

Nagasaki Shipyard was the location of Mitsubishi Heavy Industries (MHI) Group’s first business, but it has since evolved. Today, as well as continuing the long tradition of shipbuilding, it has also become a hub for producing components for aircraft jet engines.

So what is the story of Nagasaki Shipyard and how did a 19th century hub of maritime industry start a leading aviation business?

The shipyard’s roots

The origin of the Nagasaki Shipyard starts — perhaps rather uniquely for a shipyard — when Japan was in a state of isolation from most countries.

After a period of unfettered trade and widespread Christianity, Japan decided to begin a period of isolation starting in the 17th century, introducing maritime restrictions that would last well into the 19th century. During this period, the only Western contacts permitted were with the Dutch, who stayed on the artificial island of Dejima, off Nagasaki.

However, innovations were required to keep Japan relevant in an industrializing world. In 1857, the construction of the Nagasaki Yotetsusho — the Japanese word for foundry — was carried out under the leadership of Dutch engineers. It was completed in 1861 and renamed as Nagasaki Seitetsusho, or ironworks, in the same year. By 1879, the first dry dock — a dock that could be drained to repair ships — was completed. It was the biggest dry dock in all of Asia at the time.

Enter Mitsubishi

The founder of Mitsubishi, Yataro Iwasaki, born in 1835, leased the Nagasaki shipyard (former ironworks) from the Japanese government in 1884 and entered into shipbuilding on a large scale, completing MHI’s first iron ship Yugaomaru in the same year. A few years later, Mitsubishi, then run by Iwasaki’s brother Yanosuke, bought the Nagasaki site outright.

During this period, the shipyard remained at the forefront of technological innovation. In 1908, Japan’s first power generating steam turbine was completed at the Nagasaki shipyard. And the country’s first electric-powered hammer head crane was operational a year later.

The shipbuilding business was later turned into Mitsubishi Shipbuilding Company and, in 1934 the company was relaunched as Mitsubishi Heavy Industries, with ships continuing as one of its major product lines.

In 1942, one of the largest battleships in the world, the Musashi, was completed and launched.

New waves of innovation

The middle of the 20th century was a period of decentralization for MHI, which split into three companies in 1950 before remerging in 1964. Over the next 35 years, the newly named Nagasaki Shipyard and Engine Works spread out into three sites: Nagasaki Plant, Koyagi Plant and Isahaya Plant.

After the completion of the first marine boiler in 1885, MHI expanded into products including engines, turbines, propellers and turbochargers. The company entered the market with a water-cooled turbocharger in the 1950s, developing the world’s first non-cooled turbocharger by 1965 and building the MET Turbocharger brand.

During the 1970s, innovation at Nagasaki helped to increase power plant capacity and efficiency to meet surging electricity demand, delivering thermal and geothermal power plants for Japan and overseas.

In the 1990s, MHI completed luxury passenger cruise ships at the Nagasaki shipyard, including the Crystal harmony (Asuka II), and also opened up electrical and space equipment shops. And, in 2005, the cable-stayed Megami Bridge was constructed at the entrance of the Nagasaki port.

The modern shipyard

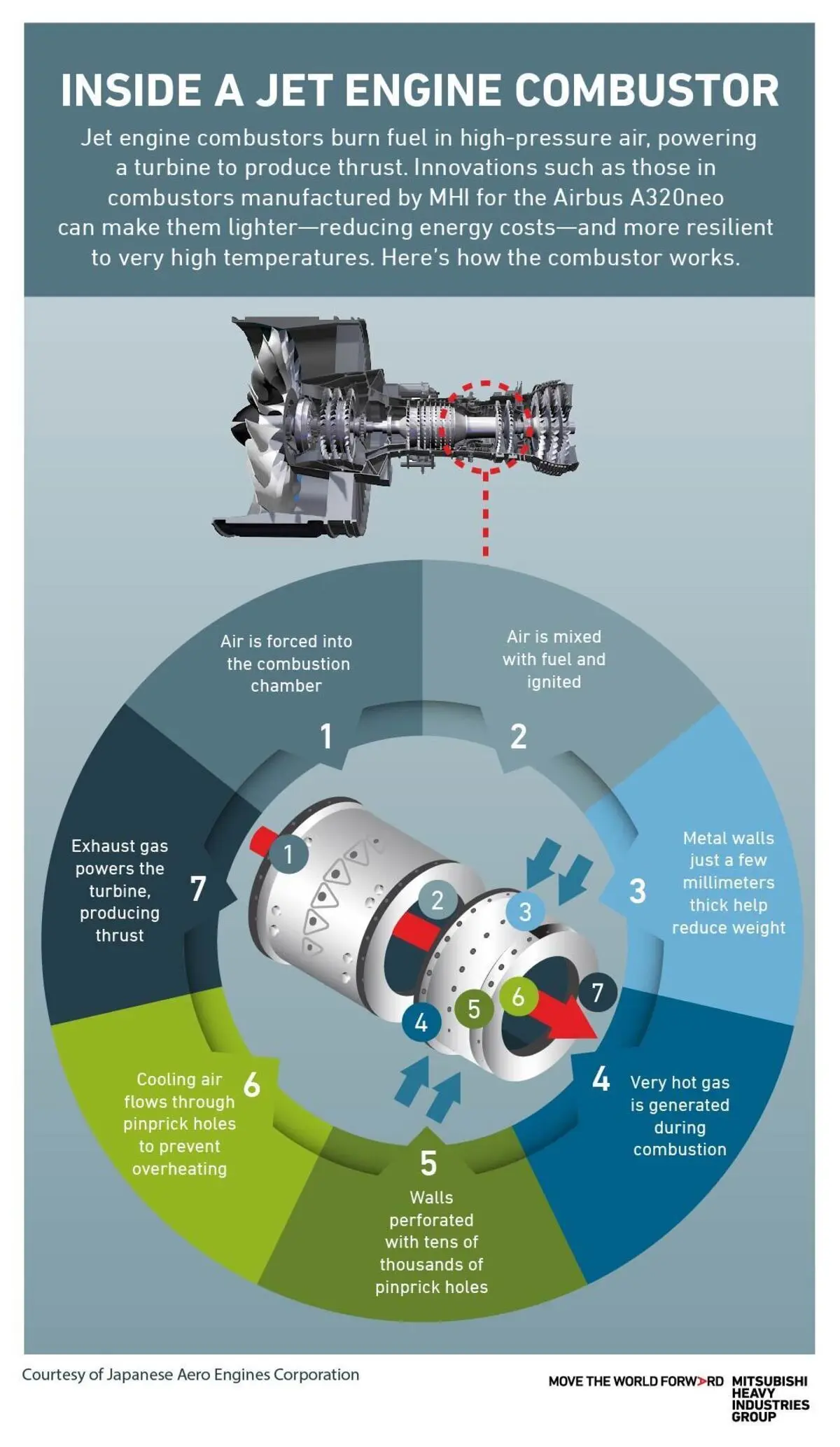

MHI continues to invest in the site. In 2020, just eight months after opening, the company’s Aero Engines plant in Nagasaki completed its first combustor for the Airbus A320neo, and plans are already in place to nearly double the size of the plant by early 2024 to meet rising demand in the post-COVID era.

Automation is also now in place, and MHI uses Internet of Things (IoT) and AI technologies at the site.

From ships to jet engines, the Nagasaki Shipyard and Machinery Works has been at the forefront of technical innovation for 165 years. Continued innovation and investment means it looks set to continue writing its place in history.