MHI Thermal Systems Introduces Hydrolution PRO Series to the European Market

Mitsubishi Heavy Industries Thermal Systems, Ltd. (MHI Thermal Systems), a part of Mitsubishi Heavy Industries (MHI) Group, is to add the “Hydrolution PRO” series of air-cooled heat pump chillers (1) to its product lineup for the European market. This series consists of three models with capacities of 50kW/75kW/100kW classes. These models are designed to suit various applications, ranging from space cooling/heating in residential and office buildings to cooling/heating needs in industrial and IT settings. The market launch will initiate with the 50kW-class model in spring 2024, followed by the introduction of other models.

Mitsubishi Heavy Industries Thermal Systems, Ltd. (MHI Thermal Systems), a part of Mitsubishi Heavy Industries (MHI) Group, is to add the “Hydrolution PRO” series of air-cooled heat pump chillers (1) to its product lineup for the European market. This series consists of three models with capacities of 50kW/75kW/100kW classes. These models are designed to suit various applications, ranging from space cooling/heating in residential and office buildings to cooling/heating needs in industrial and IT settings. The market launch will initiate with the 50kW-class model in spring 2024, followed by the introduction of other models.

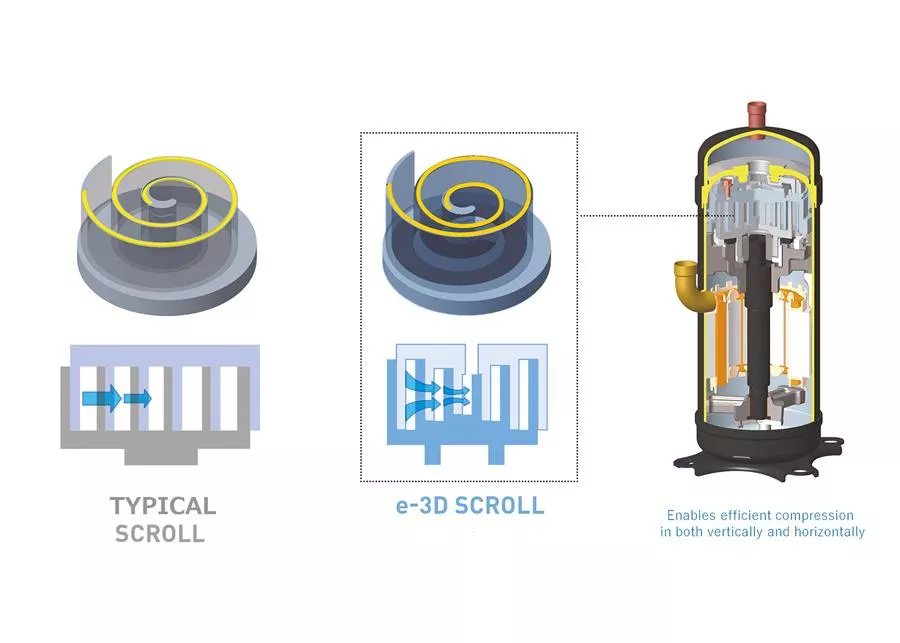

With the increasing environmental consciousness in Europe urging for reducing the amount and lowering Global Warming Potential (GWP) of refrigerant used in equipment with refrigerant (2). As one of the countermeasures, MHI Thermal Systems adds the air-cooled heat pump chiller which is the water circulation system to its product lineup. Adoption of the R32 refrigerant (675 GWP), already widely used in residential air-conditioners, in place of R410A refrigerant (2,090 GWP), common in air-cooled heat pump chillers, has reduced GWP to approximately one-third. In addition, proprietary technologies such as an advanced “e-3D scroll” compressor contribute to the energy-saving performance and environmental protection by delivering the industry’s top-tier (3) SCOP (4) of 4.59 by 50kW-class, combined with an approximately 43% (5) reduction in refrigerant charge volume.

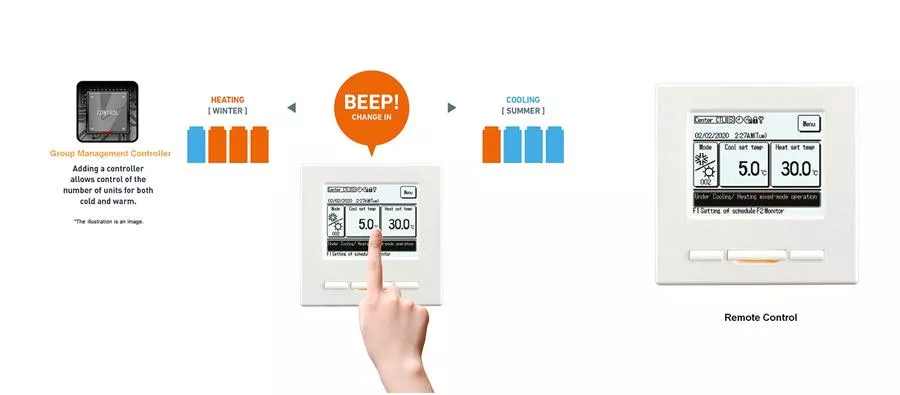

The compressor of the “Hydrolution PRO” Series features an advanced “e-3D scroll” compressor, which compresses both vertically and horizontally to reduce mechanical loss with a more compact compressing structure compared to the typical scroll compressors, thereby enhancing efficiency during low loads significantly. This compressor and water pump are inverter-controlled which enables optimal operation control depending on the load. The remote control allows the setting and adjustment of up to 20 air-cooled heat pump chillers with intuitive touch operation. A calendar function is integrated into the remote control empowers users to create customized and optimized operation schedules, adjusting multiple units for both cooling and heating according to seasonal variations and load requirements for mixed cooling/heating control. Furthermore, the newly developed group management controller optimizes the number of operating units in line with the equipment load and performs precise operation control. Modbus® communication is equipped as standard, and this allows the easy connection with the upper supervision control system to visualize energy.

E-3D Scroll Compressor

MHI Group, in accordance with its Carbon Neutral Declaration to achieve net zero emissions by 2040, is currently taking steps to reduce CO2 emissions both from its own plants and associated facilities involved in production activities, as well as from customer facilities that use its Group products. As a key member of the Group, MHI Thermal Systems remains committed to harnessing its technologies and products to drive greater energy efficiency and environmental sustainability. Leveraging its extensive technological expertise facilitated by synergies within the Group’s diverse operations, MHI Thermal Systems is dedicated to delivering optimal thermal solutions that support the journey towards carbon neutrality.

Remote Control Operation

Notes

- A heat pump chiller is a unit that creates and supplies hot and cold water to office buildings and industrial facilities such as factories for air-conditioning and other applications. Heat pump chillers are used mainly in cooling applications, but as the term “heat pump” indicates, they also can serve to heat water to high temperatures. They consist of circuitry using a refrigerant and water circulation system. The refrigerant and water perform heat exchange through a water heat exchanger.

- The lower the value, the higher the level of environmental impact. CO2 has a GWP of 1.

- According to MHI Thermal Systems’ research as of March 2024.

- Seasonal Coefficient of Performance. It is the performance indicator during the heating season. The higher the value, the greater the energy saving.

- Comparison with MSV which adopts R410A refrigerant manufactured by MHI Thermal Systems.